Adjusting Audi A4 Clutch Engagement Height

Prior Experience: None needed, very easy to do

Cost: $25

Time: 1 hour

| Discuss this mod - Here | ||

| NOTE: All pics are hyperlinked to higher resolution versions. | ||

It is not uncommon for aftermarket clutch kits to drastically change your clutch pedal engagement point. With the Southbend OFE SS clutch, many people complain about the low engagement point. With this clutch, the pedal has to be put all the way to the floor to disengage, and will re-engage as soon as you lift the pedal off the floor. If you do not like this, you can adjust the engagement point my modifying the slave cylinder push rod length. This writeup will show you how to do this. Most of this information is not new and had been discussed on the forums, but since I was doing it, I figured I would write it up. |

||

SUPPLIES - The supplies on this could vary. If you are trying to bring the engagement point of your clutch up off the floor, then you will be making the slave cylinder push rod longer. You can do this by making a new push rod, or by inserting some spacers under the caps of the push rod. To start, I would recommend using some spacers so you can determine a length which you find appropriate. |

||

For my clutch, I extended the push rod by placing a spacer under one of the end caps. I went to the hardware store and purchased a 1/16" cable tie which seems to work well. To the right you will see the push rod along with the end caps and the cable tie. |

||

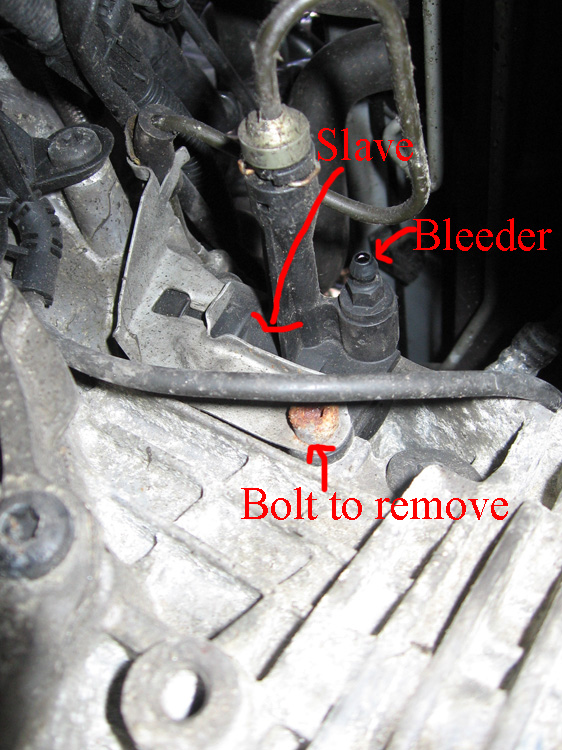

Ok so the first thing you need to do is remove the slave cylinder from the trans. It is located on the driver's side of the trans on the upper half. Some people choose to remove it from under the hood, some people choose to get under the car. I found it easier to do it from under the car. I showed how to remove this in the clutch install, but I will show it again here. If you want to find the slave cylinder from the top, you can see it (for the most part) in the pictures below. The one on the right is a zoomed in version of the picture on the left. NOTE: The coolant reservoir has just been moved out of the way. |

||

|

|

|

| Obviously it is very difficult to get good pictures down in that area, but I gave it a shot. If you are looking from under the car (approximately from the drivers front axle), the slave cylinder will look like the pictures below: |  |

|

|

In order to remove the cylinder, you have to remove the one hex bolt shown to the left. You will see that the cylinder actually is being pushed back into a seat which is outlined in red. Once you remove the bolt, you will be able to pull the slave cylinder off the seat (if you were looking from this angle, you would pull the slave cylinder towards you a bit) You want to be careful with all of this because the slave can easily be damaged, and it is connected to a hard line to your hydraulic system which can easily be damaged. |

|

When you remove the bolt, you should be able to back the slave out like what is shown to the right. You will see the dust boot which covers the push rod which we will be modifying. Be careful not to tear the dust boot. I am just recycling an image from the clutch install here: |

||

When you back the slave all the way out, you can gently pull the dust boot off of the slave cylinder |

||

You can easily pop the push rod out of the dust boot.If you couldn't tell from this point, the slave cylinder is just a hydraulic piston which pushes this rod outwards. When it pushes it outwards, it pushes against a fork which moves the throw out bearing forward to press against the pressure plate. I have more pictures of this in a bit. |

||

To make the rod longer, remove one of the end caps. You can do this using two open ended wrenches if you cant get it off with your bare hands. Just put one on each side to give you a better grip |

||

Now is the time where you can completely replace the rod, or just add a spacer under one of the caps. The rod's dimensions are as follows: Diameter - 0.275" There is no real way to tell you how long to make the push rod, but keep a few things in mind. If you are using spacers, be sure not to put a giant spacer under one of the caps. Leave enough room for the caps to get back on the rod. IF they fall off, and they fall of in the trans, you will probably have to pull the trans to take them back out. Also, by making this rod longer, you are putting more pre load on the pressure plate/throw out bearing. By doing this, it is just like pressing the clutch down slightly. IF you make them too long (in the most exaggerated case) you would essentially disengage the clutch. Obviously the system is not THAT sensitive, but you get my point. I would suggest using the spacers only to get the rod length right before you make a rod that is the correct length. A full, solid steel rod should be the permanent solution - not a rod with spacers in the caps. |

||

In this example, I put the cable tie end in one of the caps as shown to the right: |

||

| When you get to this point, you can slip the boot back onto the slave cylinder and re-install it in the trans. There is a good trick which one of the guys on the forum mentioned which helps get this thing installed. First, you want to stick the end of the slave back in the trans, and use some axle grease to grease the section of the boot shown in the picture to the left. This will prevent the boot from ripping on the install. | ||

From this inside of the trans, the slave cylinder pushes against the fork shown to the left. When the slave extends, it will push the fork out which will pivot about the pivot point and push the throw out bearing into the spring fingers of the pressure plate to disengage the clutch When installing the slave, make sure the slave is pushing against this fork! If not, you can permanently damage the slave when you press the clutch pedal - you will also shoot the push rod into the trans and have to remove the trans to get it out! |

||

If you have lined up the slave properly, you will notice that it will be difficult to push the slave back into place. You have to apply constant pressure until the slave cylinder backs up. Remember, you are pushing back against the hydraulic system here. If you are having an easy time pushing it in, then you probably do not have the slave cylinder seated properly on the release fork. Make sure it is lined up right. The goal is to get the slave pushed in far enough so you can put it back on the seat it was sitting in. There is a good trick to doing this: |

||

I understand the picture to the left is horrible, but hopefully you will get the idea... when you get the slave cylinder close to seated, you can stick a small flathead screwdriver through the screw hole on the slave cylinder, and into the hole on the trans where the slave is supposed to seat. You can then use the screwdriver to give you some leverage to push the cylinder in the rest of the way. And yes, the awful red thing is supposed to be a screw driver. |

||

Here is a version of the awful pic that a guy over on AZ drafted up.... between these two terrible images, I'm sure you will get the idea. |

|

|

After you get the slave in, you are all done. I would suggest getting into the car and pressing the clutch first lightly with your hand. If you feel like the clutch is going down very easy - then STOP. You probably do not have the slave on the "fork." If you continue to push, you will damage the slave. Go back and repeat these steps to fix the problem If you press it and it feels firm with your hand, then you are probably good to go. Give the clutch a try and see if the engagement point is better. Further spacers/adjustments can be made to fine tune it. That's it! Good luck. |

||